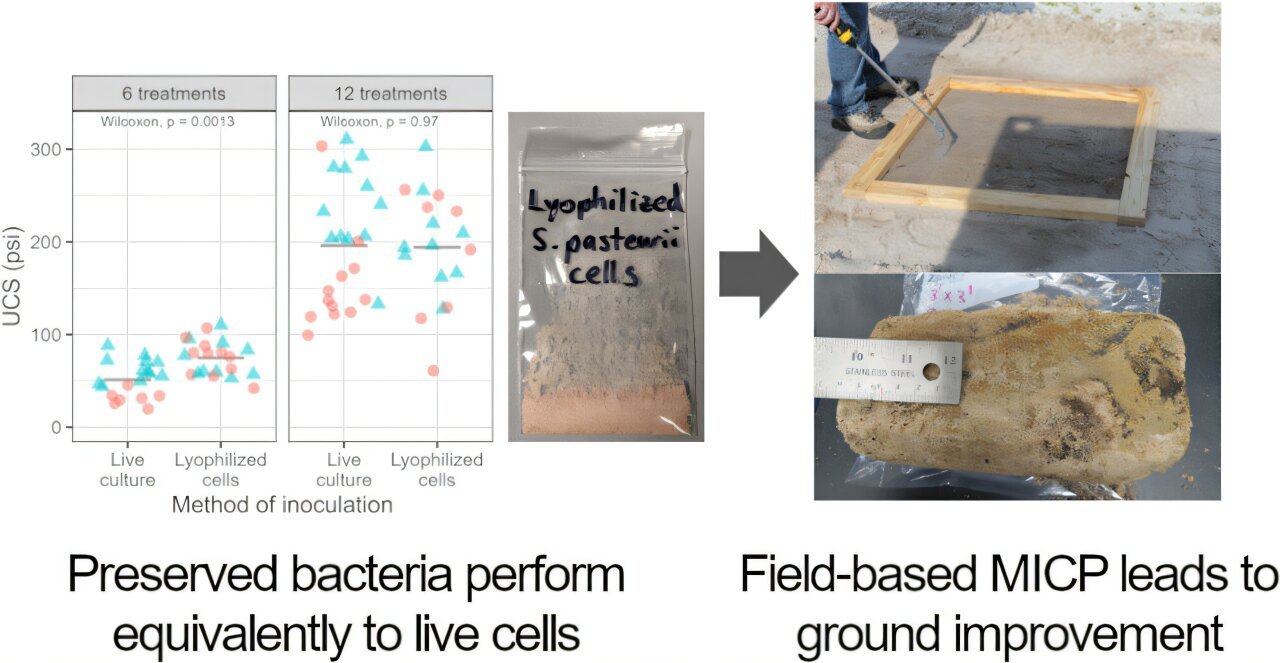

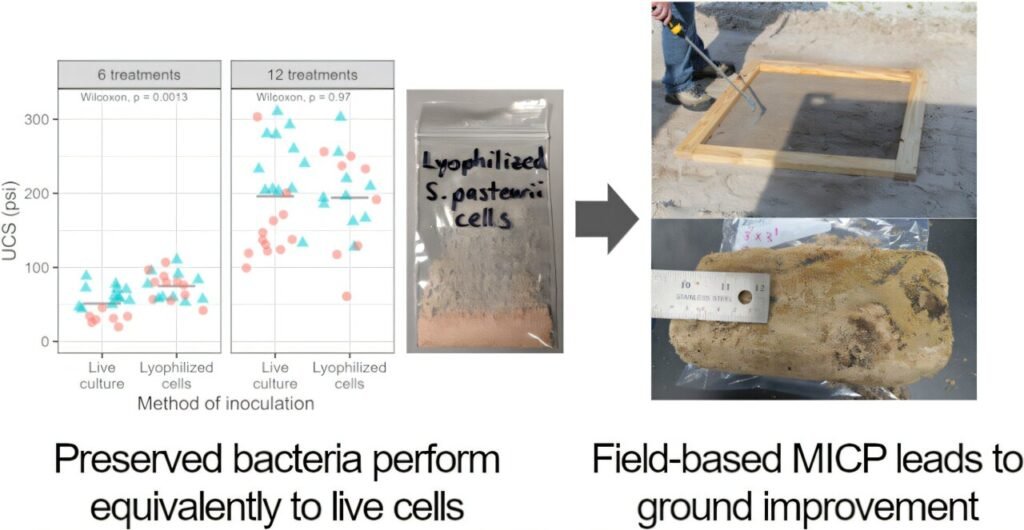

In a groundbreaking development, scientists have created freeze-dried packets of bacteria. These packets can produce biocement on demand. This innovation is revolutionizing the way we approach construction and soil stabilization.

This innovative technology is detailed in a recent study published in ACS Applied Materials and Interfaces. It could transform the construction industry by making biocement production more accessible and efficient.

What is Biocement?

Biocement is a sustainable alternative to traditional cement. It is produced by bacteria that create calcium carbonate—a mineral that binds sand and soil particles together. One such bacterium, Sporosarcina pasteurii, has shown remarkable potential in stabilizing soil and repairing cracks in concrete structures. However, growing and maintaining these bacteria on construction sites has been a significant challenge—until now.

The Breakthrough: Freeze-Dried Bacteria Packets

Led by Maneesh Gupta, a team of researchers has developed a method to preserve S. pasteurii in a freeze-dried, shelf-stable format. Inspired by freeze-dried biological components used in fertilizers, the team tested various solutions to protect the bacteria during freezing. They found that sucrose (table sugar) was the most effective protective agent. It allowed the bacteria to remain viable for at least three months when stored in resealable plastic bags.

This innovation allows construction workers to carry packets of freeze-dried bacteria. They could produce biocement on-site. This eliminates the need for specialized equipment or technical expertise.

How Does It Work?

The process involves spraying the freeze-dried bacteria with a solution containing urea and calcium chloride. The bacteria then break down the urea, producing ammonium and carbonate. When combined with calcium, this reaction forms calcium carbonate, which acts as a natural cement.

In laboratory tests, the team demonstrated the effectiveness of this method. They used the bacteria to cement sand in 3D-printed cylindrical forms. The biocement created with play sand was stronger. It is similar to that used in children’s sandboxes. It was stronger than that produced with natural soil. Additionally, PVC pipes filled with sand and treated with the bacteria showed increased strength after the biocementation process.

Field Tests Show Promise

In real-world field tests, the team applied the freeze-dried bacteria to a 3-foot (1-meter) column of soil. They then sprayed it with urea and calcium chloride. Within 24 hours, the top 3 inches (7.6 centimeters) of the soil became significantly stronger, demonstrating the potential for on-site soil stabilization.

Why This Matters

This technology could have far-reaching applications. It can repair oil wells and construct makeshift roads. Additionally, it can stabilize soil in disaster zones or military camps. It also offers a more sustainable alternative to traditional cement production, which is a major contributor to global carbon emissions.

What’s Next?

More research is needed to optimize the process for large-scale use. However, this study marks the first successful demonstration of freeze-dried S. pasteurii being used to produce biocement in the field. The team’s work paves the way for future innovations in sustainable construction and environmental engineering.

Final Thoughts

The development of freeze-dried bacteria packets for biocement production is a game-changer for the construction industry. By making biocement more accessible and easier to produce, this technology could help reduce the environmental impact of construction. It could also improve the durability and stability of infrastructure projects.

What do you think, Roommates? Could this be the future of sustainable construction? Let us know your thoughts in the comments below!